Middle duty flail mower with 1,2kg flail hammers for small and medium sized tractors from 35 hp to 75 hp with CAT I / II 3-point hitch

Bowell EFGCpro flail mowers comply to all applicable safety regulations and are CE-tested following the 2006/42/EC machine directive.

➤ for tractors with cat. I & II 3 point hitch

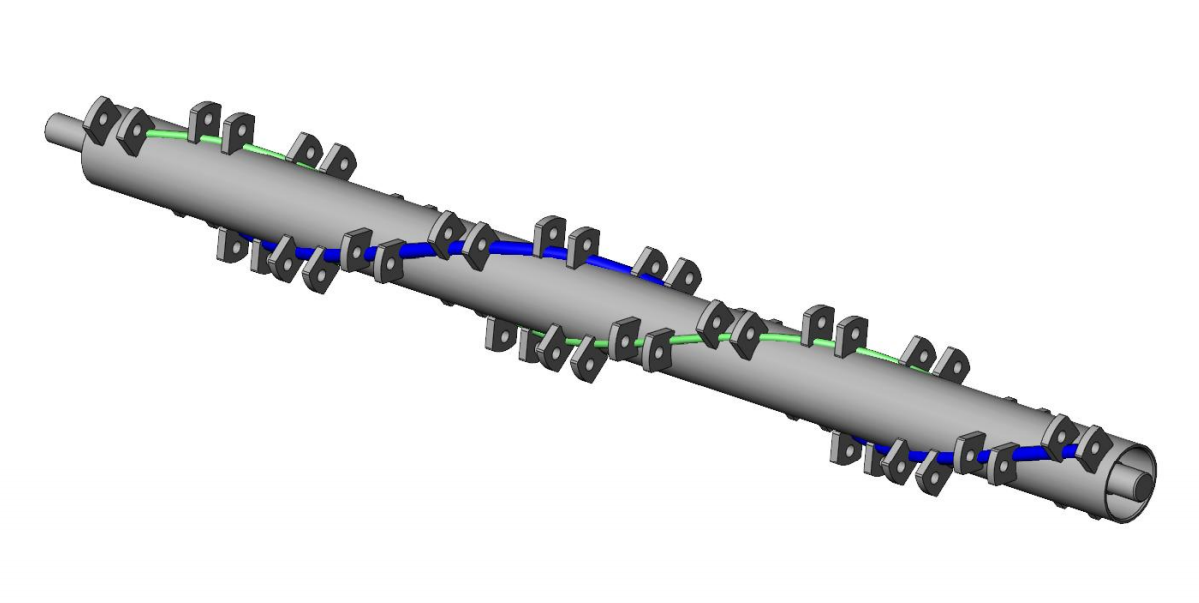

➤ performance rotor shaft with spiral arranged 1,2kg flail hammers

➤ reinforced rotor shaft with 127mm diameter and 10mm wall thickness

➤ large rear service gate

➤ up to a grass height of approx. 100 cm

➤ 155 to 220 cm working widths

➤ for 35-75 HP tractor

Including PTO shaft ✓

Including gear oil ✓

Free shipping ✓

Mower application

The Bowell EFGCpro flail mower series offers you professional technology for small and medium-sized tractors and is equipped with reinforced free-wheel angle gears from the Italian manufacturer Comer. With a working width of up to 220 cm, the solid EFGCpro mowers can be optimally adapted to the power and width of your tractor and the area to be cultivated.

Bowell EF GCpro flail mowers are equipped with Bowell Power Efficiency technology ex works. If your tractor supports a PTO speed of 1000 rpm in addition to the normal 540 rpm, you can also use the Bowell EFGCpro mowers at this increased speed. Simply replace the upper pulley with the lower pulley of the belt drive and you can achieve the same work performance much more efficiently and with lower fuel consumption. Save fuel with the new Bowell Power Efficiency technology, at no extra cost, right from the very first metre.

GCpro flail mowers are equipped with Bowell Power Efficiency technology ex works. If your tractor supports a PTO speed of 1000 rpm in addition to the normal 540 rpm, you can also use the Bowell EFGCpro mowers at this increased speed. Simply replace the upper pulley with the lower pulley of the belt drive and you can achieve the same work performance much more efficiently and with lower fuel consumption. Save fuel with the new Bowell Power Efficiency technology, at no extra cost, right from the very first metre.

EFGCpro mowers can be used effectively on medium-sized areas with grass heights of up to 100 cm that only need to be mowed two or three times a year.

Woody plant parts up to 35 mm in diameter, twigs, smaller branches and even small bushes are reliably shredded by the EFGCpro mower thanks to its approx. 1.2 kg hammer flails. EFGCpro mowers are true all-round flail mowers for tractors up to 75 hp, as they are suitable for both light tasks such as regular mowing of horse pastures and for mowing significantly thicker vegetation, yet are still extremely attractively priced flail mowers.

Technology of the EFGCpro mower

Depending on the working width, EFGCpro flail mowers are equipped with 14 to 20 of the heavy, hardened, approx. 1.2 kg new Bowell high-performance flails. The newly developed, replaceable counter blades inside the flail mowers ensure optimum results even with stubborn undergrowth and bushes.

The heavy, ball-bearing, self-cleaning rear roller is used to set the cutting height between 20 and 75 mm. The height-adjustable side skids on the flail mower prevent the mower from cutting into the ground when encountering bumps. A support at the front ensures stability when storing the equipment.

The scope of delivery includes a CE-approved drive shaft with a length between 80 cm and approx. 110 cm, which can be shortened for your application if necessary.

The reinforced Comer freewheel gearbox on the mower ensures that the heavy flail shaft can continue to run after the PTO drive is switched off without the movement being transferred to the tractor. The metal slats attached to the front of the flail mower prevent stones and other foreign objects from flying around.

SKF ball bearings with performance rotor shaft

Underneath the 5mm to 8mm thick housing of the mowers sits a laser-balanced rotor shaft with 14 to 20 hardened high-performance flails, each weighing approx. 1.2 kg. The flails have bevelled surfaces on the inside, to which deposits can hardly adhere. A further improved, spiral arrangement of the flails on the rotor shaft guarantees maximum performance with minimum effort for the tractor. The mowers of the EFGCpro series are equipped with reinforced rotor shafts that have a diameter of 127 mm and a wall thickness of 10 mm. The larger diameter also increases the flail speed and thus their performance.

The new Bowell EFGCpro mowers are equipped with SKF ball bearings, which are protected from external influences in solid, CNC-milled bearing seats. The stainless steel grease nipples are easily accessible on the outside of the mulcher housing and protected against contamination and damage by additional metal rings.

The rotor shaft of the mowers rotates, driven by the tractor's PTO shaft at up to 2200 rpm, and shreds the cut material to a minimum so that it can rot quickly. The heavy, ball-bearing trailing roller guarantees smooth running.

The PTO drive shaft is included in the scope of delivery of the Bowell EFGCpro flail mowers, as is the gear oil, which is already filled at the factory. The comprehensive operating instructions explain the assembly, commissioning and maintenance of the mowers in detail and also provide you with exploded drawings of the flail mowers' construction.

The mower is delivered fully assembled in sturdy Bowell wooden crates. Only the Cat 1 3-point mounting bracket (Cat 2 sockets are included in the scope of delivery) and the front safety bar still need to be attached to the mower, which takes about 30 minutes.

Mower with drive system and 4 drive belts

Like all Bowell mowers, Bowell EFGCpro mowers are equipped with an electronically finely balanced flail shaft. All working widths in the EFGCpro series feature a powerful 4-fold belt drive with reinforced pulleys, which enables almost 100% power transmission with barely measurable power loss and minimal wear, even with a high flail weight.

The belt cover allows the belt tension to be checked without having to remove the cover from the flail mower. This makes service and maintenance work much easier.

Features of the Bowell EFGCpro series

✅ Gearbox from COMER Italy

✅ Rotor shaft ball bearings from SKF with CNC-milled bearing seats

✅ Mulcher can be used with either 540 or 1000 rpm PTO speed

✅ Performance rotor shaft with spiral arrangement of hammer flails

✅ Reinforced rotor shaft with 127 mm diameter and 10 mm wall thickness

✅ Large service flap on the rear of the housing

✅ Stainless steel grease nipples

✅ Widened 4-fold pulleys with 17 mm wide drive belts

✅ Easy belt tension check without tools

✅ Approx. 1.2 kg hardened hammer flails

✅ Replaceable counter blades

Does the weight of the flail matter when choosing a mulcher?

If the only task is to "cut" a blade of grass, the weight of a flail is rather irrelevant. Whether a tool moving at 40 m/sec or more weighs 400, 800 or 1200 g and what shape it has is irrelevant, as all these tools are superior to a blade of grass. The longer the intervals between work cycles, the greater the likelihood that, for example, small bushes will have grown after 3 to 6 months, that bramble shoots will have reached a diameter of 2 cm or more, or that spring or autumn storms will have blown larger branches off trees. So if, after six months, there is not only green material on a meadow, such as grass, thistles or nettles, but also small bushes have grown and branches several centimetres in diameter are lying in the grass, heavier flails are essential if you want longer intervals between two mulching operations. A prerequisite for less frequent mulching, e.g. to save fuel and time, is therefore a sufficiently high flail weight.

How tall can the grass be if I want to mulch?

The larger the interior of a flail mower, the more grass can be processed per unit of time, provided that sufficient tractor power is available. The depth and height of the mower housing determine the volume available inside. After the blades of grass have been cut, they must be shredded at high speed by the replaceable counter blades inside. The more space the material has in the housing, the faster and more thoroughly it is chopped. The larger the interior of a mulcher, the taller the grass can be when mulching and the less often the process needs to be repeated during the year. So, for example, those who value insect protection will be more likely to opt for a flail mower that can also handle tall grass later in the year.

It should be noted that machines with a large interior are often more expensive than those with a small interior and usually also require more tractor power. A product range with closely graded models, such as that offered by Bowell, makes it possible to find the optimal mulcher for your tractor and application.

Are the diameter and wall thickness of the rotor shaft something I should pay attention to when buying a machine?

The greater the working width of a flail mower, the weight and number of flails attached to it, the more likely it is that imbalance and vibrations will occur at high rotational speeds of more than 2100 rpm. This would disrupt or render operation impossible. The EFGCpro series from Bowell comes with a working width of up to 220 cm and a large mower interior, so that you can get by with 1 to 2 passes per year, depending on the weather. The grass can be up to 100 cm high. Heavy hammer flails are very helpful for effectively shredding woody plants and branches. To prevent these from generating vibrations at high rotational speeds, rotor shafts with a larger diameter and greater wall thickness are an important prerequisite for professional work. A positive side effect of a larger rotor shaft is also a higher flail speed, which is accompanied by correspondingly higher impact force.

Does the rear maintenance flap on a mulcher offer any benefits?

Maintenance flaps on rear mulchers are usually located on the rear of the mulcher housing and make the rotor shaft of a mulcher easily accessible. Since the rear hydraulics of a tractor are usually not able to lift the machines high enough to allow cleaning and maintenance work to be carried out comfortably, a maintenance flap makes this work much easier. It is often assumed that the maintenance flap can also be used to achieve better mulching results when the flap is open during operation. For safety reasons, it is not permitted to mulch with the flap open, as stones can be thrown out and fly extremely far. However, with the maintenance flap open, the mulching result is not better, but significantly worse, as the grass is shown a way out of the mulcher housing during the shredding process. As a result, blades of grass that are too long remain on the lawn, which can prevent light and air from reaching the lawn underneath and cause it to start rotting.

A maintenance flap also always means less stability for the mulcher housing. To ensure that this does not have a negative impact on the longevity of the machine, the housing must have a material thickness of 4 to 5 mm and additional bracing. In addition, the rotor shaft and trailing roller must have the highest possible diameter and wall thickness. That is why EFGCpro mulchers from Bowell use rotor shafts with a diameter of 127 mm and a wall thickness of 10 mm.

At Bowell Tractor, we are confident that you will not find another medium-duty tractor mulcher with a better price-performance ratio. Please compare the details of our product with other mowers on the market, as we are confident that you will agree with us.

ATTENTION

The necessary gear oil has already been filled. Lubrication points do NOT contain any lubricants! BEFORE STARTING UP, please observe the relevant instructions in the German operating manual.